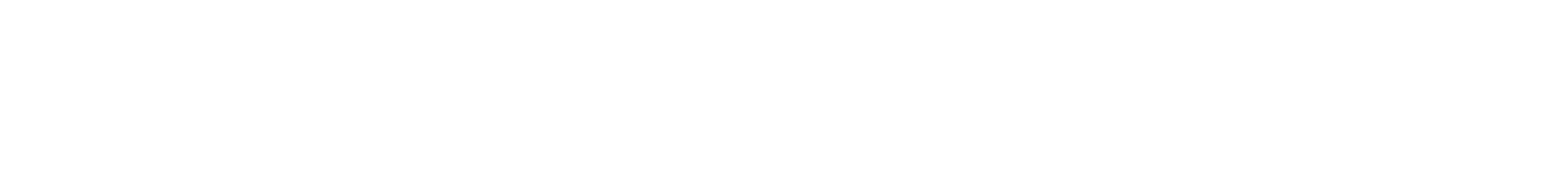

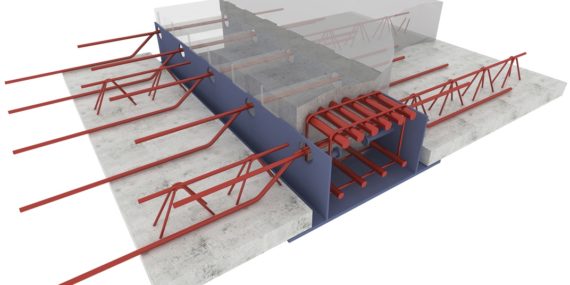

The Hybridbeam® composite beam is a prefabricated load-bearing element that is used as a flat beam to create slim floors - integrated ceilings with a low construction height. The standard design of the Hybridbeam® is flush with the ceiling.

designation: BHM Hc-Bc-W-L

|

|

designation: BHR Hc-Bc-W-L

|

|

designation: BHS Hc-Bc-W-L

|

|

The beams are made of high-quality materials:

Designations:

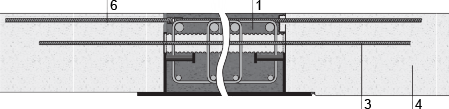

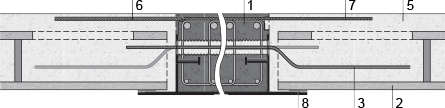

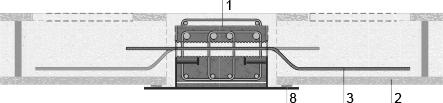

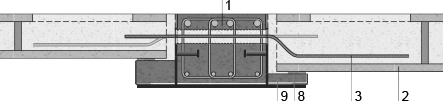

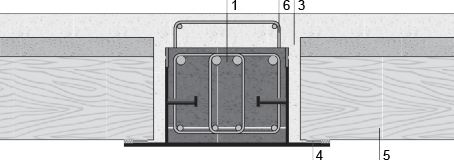

Hybridbeam® can be used in combination with hollow-channel prefabricated floor slabs in many different combinations depending on the static calculation requirements. Below are the characteristic cross-sections of the beams for the basic variants:

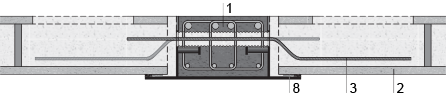

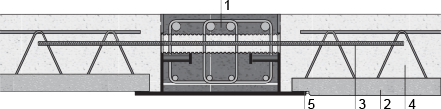

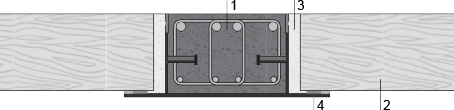

Hybridbeam® with hollow-core slabs of the same construction height.

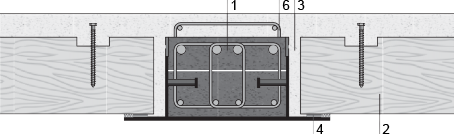

Hybridbeam® in a hollow-core slab ceiling of the same height as the beam. Structural concrete over the ceiling. With a concrete overlay thickness of more than 8 cm, it is possible to expose the connecting stirrups from the cross-section of the beam.

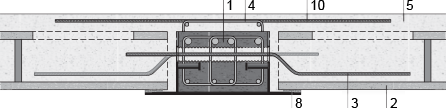

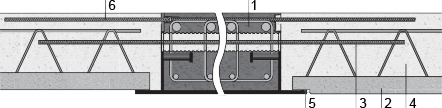

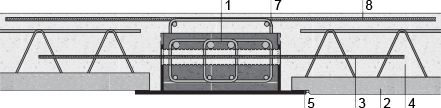

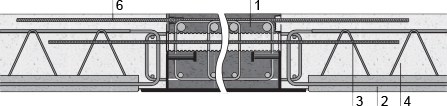

Hybridbeam® with a height equal to the height of the floor slabs with concrete topping and an option for tensile reinforcement with the upper reinforcement of the floor slab (7 - bendable reinforcement, 6 - screw-in reinforcement).

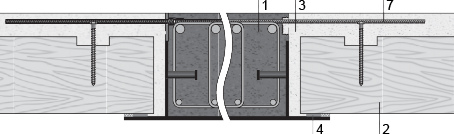

Hybridbeam® with built-in connecting reinforcement for concrete topping, provided that the floor slabs are higher than 8 cm from the beam's structural height.

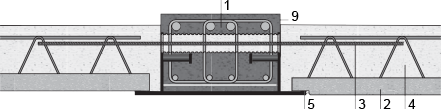

Hybridbeam® with an increased support for floor slabs (support adapted to the given height of the hollow-core slab).

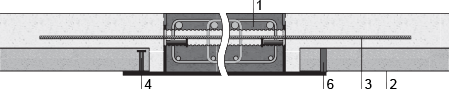

In many ceiling solutions, prefabricated composite slabs are used as the load-bearing formwork element for the composite - monolithic - ceiling structure. Standard composite (non-stressed) slabs are produced with a thickness of 7 to 8 cm of a prefabricated slab and a span of up to approx. 9 m. Such ceilings require additional support from a certain span (determined by the statics of the object) during assembly and during the maturation of the filling concrete. When using pre-stressed composite slabs, the thickness of the prefabricated element exceeds 10 cm, and the spans of these slabs reach up to 12 m. For most pre-stressed prefabricated slabs, assembly support is not provided as it is for unstressed elements.

Hybridbeam® in combination with a single-span monolithic floor on prefabricated slabs

Hybridbeam® with the continuing of the reinforcement of the concrete topping embedded in the side surface of the beam

Hybridbeam® in a multi-span slab floor

Hybridbeam® protruding above the upper edge of the floor

Raised support of a prefabricated panel

Suspended support of a prefabricated slab for composite floors

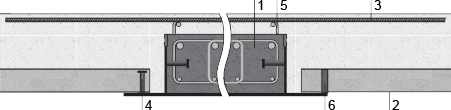

Timber is being used again in industrial (and load-bearing) structures of buildings. The structural properties in combination with the low dead weight make wood a more and more desirable material in construction - not only in the form of solid sections, but above all as wooden elements in processed form. Timber in ceiling structures is often combined with concrete, which can be seen in composite timber and concrete structures. These constructions optimally combine the physical properties of materials with such different densities.

Hybridbeam® with solid timber slabs

Hybridbeam® with protruding connecting reinforcement and composite timber slabs with concrete topping made on site

Hybridbeam® with bent or screwed-in continued reinforcement for the reinforcement of the concrete topping

Hybridbeam® with prefabricated composite timber-concrete slabs

Hybridbeam® with composite timber beams with on-site concrete topping

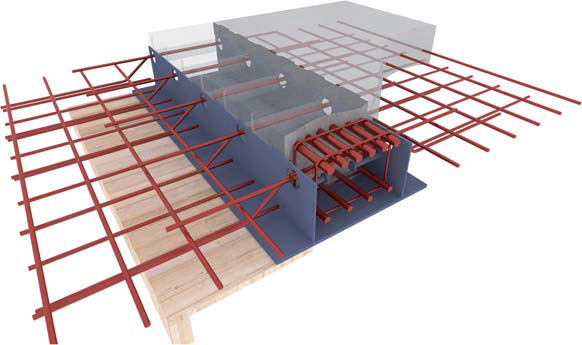

In the search for an effective cross-section of a ceiling slab, designers use composite concrete ceilings on a sheet with a corrugated or trapezoidal profile. Thanks to the combination of concrete and steel, the ceilings combine the advantages of these materials in the most effective way. These ceilings meet the conditions related to fire resistance and constitute an appropriate sound barrier between rooms. They enable the transfer of not only static loads, but also loads with dynamic characteristics. These ceilings are characterized by a perfectly low parameter of the number of structures in relation to its surface (the equivalent of hollow tile floors).

Hybridbeam® for composite floor slabs on a trapezoidal sheet with the same floor slab height

Hybridbeam® for composite floor slabs on a trapezoidal sheet with a lower height than the floor slab

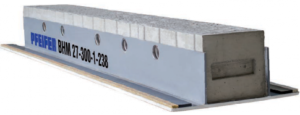

In the construction of monolithic ceilings - beam-slab or the so-called stiffening bands - Hybridbeams can be successfully used. Their use often allows to eliminate the problem of punching the ceiling in the area of the support (column, wall corner) or to reduce the height of the joist or the thickness of the strip. The combination of a beam with a monolithic floor can be achieved thanks to a variety of connection techniques; from continuing the reinforcement with the beam cross-section in a bent form, through the use of reinforcement inserts or reinforcement tightened into the reinforcement connectors concreted into the beam cross-section.

Hybridbeam® with a monolithic floor